Careers

Certified Welding Inspector

Job Overview: Certified Welding Inspector

Plans, directs, coordinates, monitors, and executes activities related to ensuring that inspections of structural steel fabrication are completed to the requirements of applicable specifications and codes. Works with company-wide QC team and fabrication crews to establish quality standards and procedures, and identify quality improvement opportunities.

ESSENTIAL DUTIES / SKILL / RESPONSIBILITIES:

- All Duties/Skills/ Responsibilities of a Senior Technician

- Ensure that the fabricated steel will fit as planned, meets customer specifications, and inspections are completed as required to support workflow and sequence

Working knowledge of AWS D1.1 and D1.5 - Ensure that accurate documentation is maintained on every project

Is responsible for assisting the Quality Control Manager in administering the AISC program at assigned plant - Ensures that all production-related employees understand and follow applicable AISC standards

- Works with other NDT inspectors to organize inspection work to be done on a daily and weekly basis

- Work closely with Production Supervisors, Engineers, and customer representatives to determine appropriate courses of action for resolution of defects

- Communicates with fabrication employees regularly

- Provides assistance and/or training where appropriate, assists in counseling employees on improving quality

- Assists in identifying and solving quality non-conformances in a timely and cost-effective manner

- Carries out new project specifications

- Manages welder certification program and ensures welders are tested per contract specification

- Monitors established non-destructive testing programs, both internal and outsourced

- Monitors internal testing program to include training, testing, and that NDT technician standards are met and documented

- Keeps current on industry trends, innovations, and changes that may affect how we manufacture and service our products.

- Maintain safe, secure and healthy environment by adhering to Company/Customer safety standards and practices and to legal regulations, alerting others regarding potential hazards or concerns.

- Ability to write and communicate Welding Procedure Specification (WPS) per code requirements

- The listing of duties and responsibilities shall not be held to exclude other duties not mentioned that are of similar kind or level of difficulty

WORK CONDITIONS:

- Must be able to work in both indoor and outdoor environments and in all types of weather conditions

- Interaction with other crew employees, as well as supervisors and client personnel

- Working in plant and/or shop areas around production machinery with extreme noise levels

- Proper personal protective equipment is required such as, steel toed or metatarsal boots, ear plugs/earmuffs, safety glasses, pants, and hard hats

- This is a safety-sensitive position. A safety sensitive job or position is where the employee holding the position has, at any time during his or her employment, the responsibility for his or her own safety or the safety of others

PHYSICAL REQUIREMENTS:

- Ability to lift and carry 60 pounds

- Sufficient clarity of speech and hearing or other communication capabilities which permits employee to communicate effectively

- Ability to sit for prolonged periods of time

- Sufficient vision or other powers of observation which permits employee to investigations

- Sufficient manual dexterity which permit the employee to perform routine office duties

- Sufficient personal mobility and physical reflexes to perform office duties and travel when necessary to off-site locations

EDUCATION/EXPERIENCE:

- Associates degree in Welding Technology or related field preferred

- Current Certified Welding Inspector (CWI) certification (AWS D1.5 preferred), or ability to obtain certification within 6 months of hire

- Level II MT, PT, UT certifications preferred, but not necessary

- Five or more recent years’ experience in steel fabrication

- Ability to read and interpret drawings and Weld symbols

- In depth understanding of blue print drawing and shop drawings

- Advanced math skills

- Have professional demeanor and appearance

- Able to analyze complex problems and contribute to generating solutions

- Deal effectively with time pressures, long hours, rapidly changing priorities, and stress

- Possess a valid driver’s license and be insurable to drive (may require some travel to job site)

- Must have a good track record of conducting business honestly and ethically

- Strong computer literacy skills with MS Office (Excel, Outlook and Word)

- Excellent organization and communication skills – both written and oral

- Willing to work any shift and extended hours if need

Job Descriptions

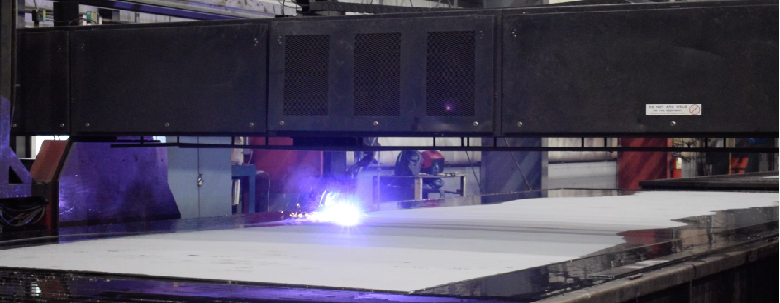

Industrial Welders

Fabricates and repairs material by using the appropriate welding processes and techniques in the vertical, horizontal and overhead positions. Welding is done utilizing the SMAW (stick), GMAW (MIG), FCAW (flux-core) and SAW (submerged arc) processes when necessary as called out by the drawing.

Industrial Electricians

Participate in the construction, installation, modification, maintenance and repairs of electrical appliances, systems, facilities and related electronic controls of varying complexity.

CNC Plasma Operators

Candidate will be assigned to operate and set up conventional or numerical control (NC) machines to fabricate parts, applying knowledge of shop math, machinability of materials and drawings.

Fitter

Measures and lays out materials, subassemblies and complete assemblies using approved drawings, as well as check for fairness and squareness of subassemblies as they are produced.

Machine Operator

Machine operator consists of manually operating various automated machines to produce quality welds; such as deep flange welder, panel welder, slot & seam welder and the one-sided welder.

Industrial Painter

Sandblasts and hand tool cleans to prepare steel to specification. Paints using airless spray system to specification as well as some brush and roll application.