Careers

Industrial Welder

Job Overview: Industrial Welder

Fabricates and repairs material by using the appropriate welding processes and techniques in the vertical, horizontal and overhead positions. Welding is done utilizing the SMAW (stick), GMAW (MIG), FCAW (flux-core) and SAW (submerged arc) processes when necessary as called out by the drawing.

JUST ANNOUNCED!

2024 HOURLY WAGE INCREASE!

Starting Pay: $18.00 to $35.00 /hour*

(*Based on experience)

ESSENTIAL DUTIES / SKILLS / RESPONSIBILITIES Welder III:

- Perform tack welds working with a fitter

- Perform tack welds on work that has already been laid out

- Perform tack welds or continuous welds in the flat position using a wire feeder or a welding rod as directed

- Perform vertical fillet welds as directed by supervision

- Does not require knowledge of all welding techniques

- Ability to follow verbal and or written instructions

- Ability to establish working relationships with other employees and supervisors

- Ability to work independently and in a team setting

- Acceptable attendance, following the established Company policies

- Additional tasks and duties as assigned, to support and improve the overall team operations

- Please note overtime is an essential function of this position

Welder II

- Essential Duties as above

- Certified to an intermediate level of skill and knowledge to ensure mechanical strength on diversified assemblies and parts

- Select and set-up welding equipment and inspect their welds to ensure compliance to standards and specifications

- Knowledge of weld symbols and corresponding specification requirements is essential

- MIG welding and Stick welding capability in all positions is a requisite.

SKILL FACTORS:

- Ability to weld in the horizontal, vertical and overhead positions using MIG and Stick type welding

- Set-up appropriate weld machines using knowledge of weld machine settings in conjunction with weld symbols shown on drawing.

- Weld tacks, fillets and butts in all positions at production rate.

- Knowledge of all related welding safety issues is a requirement.

- Ability to inspect welds to determine that they meet standards and/or specifications a must.

Welder I

- Essential Duties as Above

- Certified to an advanced level of skill and knowledge to ensure mechanical strength on diversified assemblies and parts inclusive of set-up of weld equipment, welder settings, and type of welds required

- Knowledge of all welding techniques required including Stick, MIG, Sub Arc, Flux Core and Submerged Arc.

- Stick and MIG welding in all positions is a requirement; horizontal, vertical and overhead with specification compliant Quality.

- Knowledge of all welding symbols as stipulated by the manufacturing drawings and their respective applications.

SKILL FACTORS:

- Weld utilizing Sub Arc, Flux Core and Submerge Arc techniques when necessary as called out by the drawing. Quality welds should be made manifest utilizing all the aforementioned processes/techniques

- Perform carbon Arc welding and back-gouging as required with proficiency and at a production rate

- Weld tacks, fillets and butts at production rate with little or no pickup

- Superior ability to inspect welds to determine that they meet standards and/or specifications a requirement

WORK CONDITION:

- Environment is that of a heavy industrial worksite.

- Outdoor elements are a factor.

- Exposure to air particles, such as dust, chemical (paint, oil, gas, diesel fumes) and weld smoke

- Exposure to loud, penetrating noises in some work areas

- Proper personal protective equipment is required at all times, such as metatarsal boots, ear plugs/ear muffs, safety glasses, pants, hard hats and possible respirator use

EDUCATION/EXPERIENCE:

- High school diploma or equivalent is preferred, however, is not required

- Technical school training, preferred, however, is not required.

Job Type: Full-time

Starting Pay: $18.00 to $35.00 /hour based on experience.

Experience:

- Welding: 1 year (Preferred)

Education:

- High school or equivalent (Preferred)

Job Descriptions

Industrial Welders

Fabricates and repairs material by using the appropriate welding processes and techniques in the vertical, horizontal and overhead positions. Welding is done utilizing the SMAW (stick), GMAW (MIG), FCAW (flux-core) and SAW (submerged arc) processes when necessary as called out by the drawing.

Industrial Electricians

Participate in the construction, installation, modification, maintenance and repairs of electrical appliances, systems, facilities and related electronic controls of varying complexity.

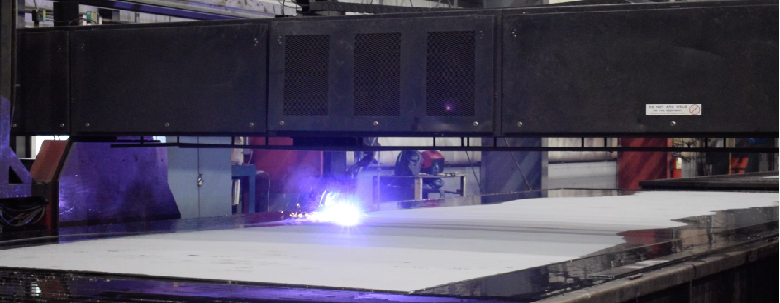

CNC Plasma Operators

Candidate will be assigned to operate and set up conventional or numerical control (NC) machines to fabricate parts, applying knowledge of shop math, machinability of materials and drawings.

Fitter

Measures and lays out materials, subassemblies and complete assemblies using approved drawings, as well as check for fairness and squareness of subassemblies as they are produced.

Machine Operator

Machine operator consists of manually operating various automated machines to produce quality welds; such as deep flange welder, panel welder, slot & seam welder and the one-sided welder.

Industrial Painter

Sandblasts and hand tool cleans to prepare steel to specification. Paints using airless spray system to specification as well as some brush and roll application.